Hatchery: The hatchery of the Institute includes a plankton production lab where phytoplankton and zooplankton is cultured.

The larval rearing is performed applying both semi-intensive and intensive methods. A Mesocosm hatchery is operated with 6x40m3 tanks for acquiring basic biological information of the species reared.

An intensive hatchery is also operated for precise experiments.

The facility includes, 8 closed water systems of 2×500 l tanks and 3 closed water systems of 3×2000 l tanks. The main applied method is the pseudo-green water rearing.

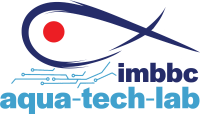

The facility includes also a pre-growing zone with 18x10m3 tanks (photo: Pre-growing tanks 1; Juveniles). Feeding is performed using an automated system developed at the lab.

The species under study are the E. seabass, the gilthead seabream, the greater amberjack and the meagre, while studies on the bluefin tuna, the atlantic bonito, the wreckfish and several members of the sparidae family have been also implemented.

The facility serves research for the definition of species specific hatchery technologies with emphasis on the optimal environmental parameters (light, tank hydrodynamics) (photo: tanks of different color; water current velocities….) and the feeding requirements of the larvae. Recently this resulted in the definition of husbandry practice for the rearing of greater amberjack within the Diversify project (https://www.diversifyfish.eu/). This activity is further developed today in the frame of a new project, the “Greater amberjack”.

The effect of larval rearing on the subsequent performance of the fish represent a major objective of the activity. Today, the facility is used for implementing research within “Performfish” to study the effect of early temperature regime in the performance of E. seabass and the gilthead seabream.

Ongrowing cage farm: In Souda Bay, a pilot aquaculture net pen cage unit is operating since 2000.

Currently the unit consists of 16 cages 6x6m (each with the possibility to form 4 smaller of dimensions 3x3m) (the farm 1). In addition, there are 4 circular cages with diameter of 12 m.

The operation of the unit is served by a floating platform and a storage hut.

Part of the energy requirements are covered by photovoltaic cells and a wind turbine.

Several species (E. seabass, g. sea bream, meagre, greater amberjack and other Mediterranean species) are bred in the unit.

The farm serves the implementation of research projects aiming at the improvement of the rearing parameters and development of husbandry practices.

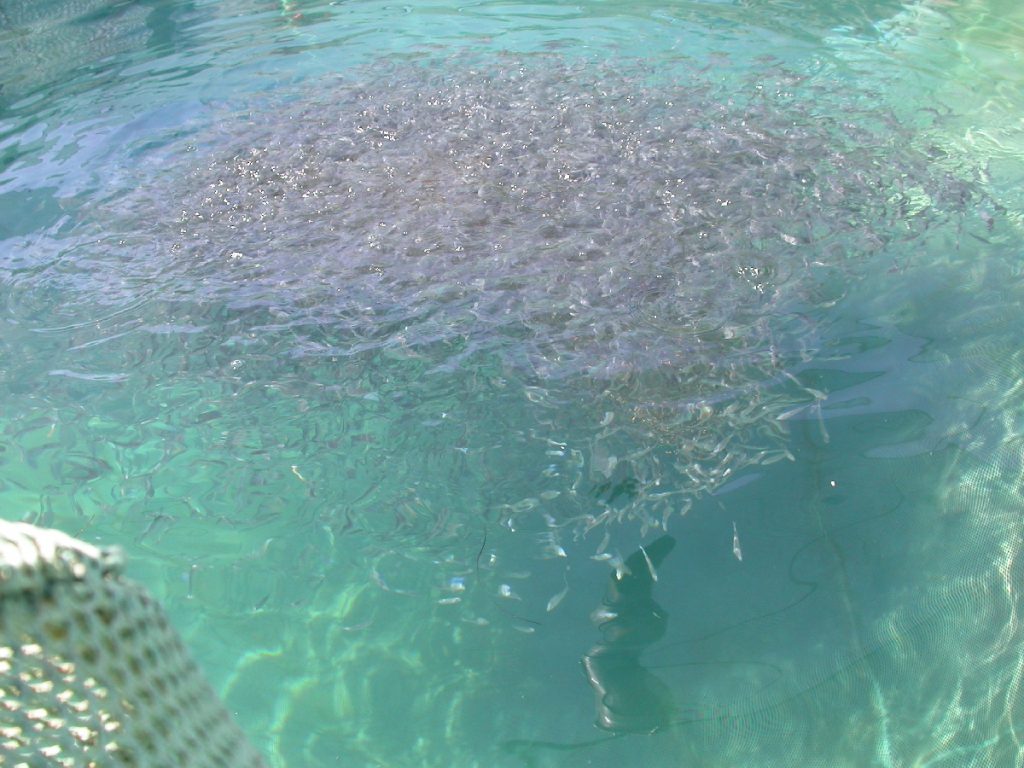

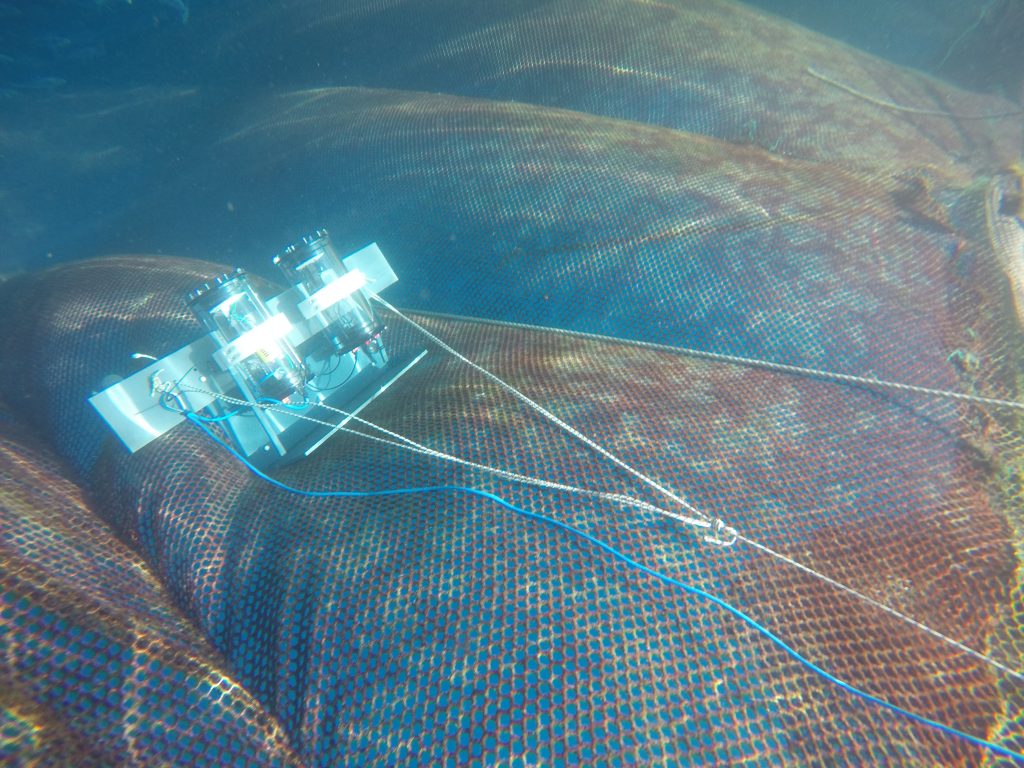

A submerged cage, operated at 45m depth was installed

and used for the rearing of red porgy resulting in the proper coloration of the species.

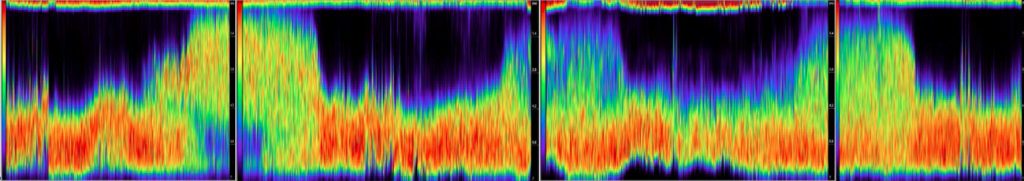

The study of fish behavior during standard rearing conditions and during stress using echosounders

targets to understand the physiological mechanisms involved and to develop methods – indicators for monitoring and management of farmed populations during the production process. The facility has been used for experiments in the Diversify., and the Aquaexcel2020 projects

Tech Lab: The new requirements for the better management of the farms and also φορ the “offshore” aquaculture have led to the creation of a new laboratory. The concepts of precision farming and automation are in the core of its activities.

New tools towards human free operational schemes are developed for cage farming.

An Autonomous Underwater Vehicle (AUV) for frequent monitoring of cage integrity and net condition has been developed and demonstrated . The AUV system uses advanced machine vision techniques and connects to communication networks to alert upon problem detection. The system is developed within the TAPAS project.

A system for the automatic estimation of fish biomass and in particular the individual fish size using stereoscopy is developed in the frame of the Performfish project.

The continuous on-line monitoring of various parameters during rearing for a better management in farms is studied in the iFishIENCi project where our group is involved in the development of tools for the monitoring of fish behavior.

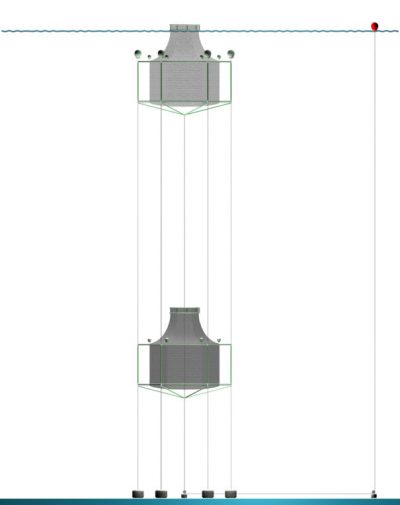

The group was involved in the development of offshore aquaculture concepts for multipurpose oceanic platforms, developing the aquaculture module with emphasis on the synergies with other activities, modelling technologies and analyzing the economic characteristics of the activity. The work in the frame of the TROPOS project resulted in the design of multi purpose platforms that combine wind energy harvesting and aquaculture activities (photo: prototype…).

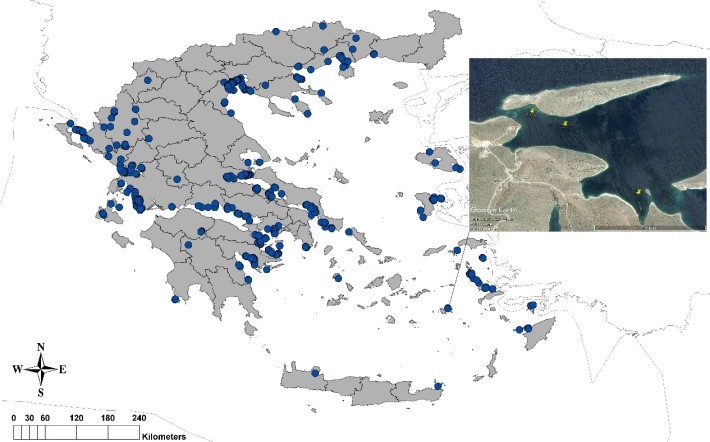

Towards the development of tools for the better management of farms, a computer-based Decision Support System (DSS) has been developed in the frame of the Climefish project to help farmers anticipate climate change effects in the greek aquaculture (photo: DSS user interface). For this a GIS application with the location of the greek farms has been also implemented.

The Tech Lab has recently won 3 new projects to further develop its activities.

The “i-fish” (link to a new page) project aims to develop tools for the better management of aquaculture cage farms.Two other projects are related to the development of new material for aquaculture nets. The first explores the characteristics of different materials and techniques (https://www.hmu.gr/antifoul/), while the second aims the piot scale application of the findings.